Electrical Software design Services in Malaysia

- Printed Circuit Board (PCB) Design and Layout Services

- Embedded Hardware Design & Development Services

Why Choose Our Electrical Engineering Software Services

Antlysis Design performs all aspects of product development, from electrical software design services to volume production. Experts in software architecture design, software process development, and programming, Antlysis’s embedded software development team has programmed firmware for a wide variety of applications in the automotive, medical devices, industrial controls, consumer electronics, IoT, and other edge device industries. Our electrical engineering software services also includes helping our clients write device drivers and other low-level code in the assembly languages of microcontrollers based on ARM and other instruction sets from chip-makers such as Microchip, Atmel, Texas Instruments, Intel, ST Micro, NXP, Freescale, and Renesas.

Hardware development

- Bring-up of device drivers

- Secure bootloader development on custom hardware

- RTOS and other operating system porting, including board support packages (BSPs)

- Third-party software package porting or middleware and protocol stacks

Software development

- tool setup and configuration (e.g., static analysers)

- Firmware design, coding, and testing in C/C++ and assembly

- Software architecture review and detailed design reviews

- Cryptography design and implementation

Our engineers work with the following programming languages:

- C

- C++

- Linux

- Nodejs

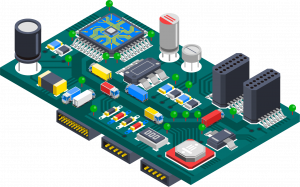

- Reactjs

We provide custom printed circuit board design and layout for analogue, digital, and mixed signal boards for a variety of electronic systems and fields of application. You might already have design schematics created and require a PCB layout from them, or you might be looking to improve and optimize your existing design for cost-effective assembly. We can help you build PCB designs, including high speed PCB design, from scratch, as well as provide technology consulting services to solve any technical complexities you might have.

What’s included?

From PCB schematic design and PCB board layout to testing, validation, and certification, we take responsibility for the full cycle of the PCB design process. See the detailed breakdown of our printed circuit board design services below.

Writing a technical specification

Preparing a project specification is an important part of a custom PCB design service. It may include technical requirements, block diagrams, deliverables, assumptions, a preliminary bill of materials (BOM) and BOM costs, tools and technologies specified for the project development. The specification allows our designers to stay on the same page with our customers and meet their expectations.

Schematic design

The process of PCB board design always starts with schematics. A schematic or a circuit diagram conveys the electrical connection between different electrical components like integrated circuits (ICs) and discrete components. To deliver this PCB design service, we use professional CAD software, such as Altium Designer, to define modules and design the connectivity between different components.

PCB layout

Once the schematic is imported to the PCB layout, we manually place components on the board and route the traces. We take into consideration the number of required layers and the dimensions of components that may be limited by the size of the housing. Within our PCB layout services, we analyse signal integrity and evaluate electrical limitations to ensure the safety of the board level architecture. For a complex layout, we include various simulations into our custom circuit board design services. Our specialists arrange proper conductor routing, which is the primary factor affecting the price of PCB manufacturing. We run DFM/DFA analysis to minimize PCB design revisions, cut development costs, and reduce time to market.

Once the schematic is imported to the PCB layout, we manually place components on the board and route the traces. We take into consideration the number of required layers and the dimensions of components that may be limited by the size of the housing. Within our PCB layout services, we analyse signal integrity and evaluate electrical limitations to ensure the safety of the board level architecture. For a complex layout, we include various simulations into our custom circuit board design services. Our specialists arrange proper conductor routing, which is the primary factor affecting the price of PCB manufacturing. We run DFM/DFA analysis to minimize PCB design revisions, cut development costs, and reduce time to market.

PCB fabrication and testing

Once our PCB design layout is approved for production, we export it into the format the manufacturer supports. We prepare a bill of materials (BOM) and Gerber files that describe design requirements for each image of a circuit board. Manufacturers use this documentation as a reference for board fabrication and PCB assembly. For certain projects, we also create a 3D model of a PCB to make sure it fits the housing. Testing is essential for both our PCB layout design services and the fabrication stage. We provide the manufacturer with the data and software necessary to perform an electrical and impedance test. After the prototypes are manufactured, we test them in-house.

Mass production

After the prototype validation, we prepare the files for mass production and assist the customer throughout the manufacturing process. We arrange special software, hardware, and testing procedures. Using them, the manufacturer can test each PCB at the factory.

Technical support

Upon completion of the project, we create a full document package that comprises BOM and Gerber files, 3D models, and technical manuals. In addition, we set a warranty period for our PCB design services. During this period, we fix bugs and provide other technical support covered by the warranty. After the warranty period ends, we stay in touch with our customers and can consult them when needed.

As part of our hardware design services, we provide embedded product design and development for a wide range of embedded systems. Our team can implement small-scale projects based on an 8-, 16-, or 32-bit microcontroller, design SoC-powered electronics, and build 32- and 64-bit single-board computers (SBCs). We create sophisticated embedded systems with increased security requirements and a rich collection of peripherals and I/O capabilities.

With a deep knowledge of all modern technology platforms, our embedded product design company will recommend that you choose a system on a chip, wireless module, or semiconductor device suitable for your project. Our engineers are certified hardware experts who keep up to speed with the latest advances in the field of electronic design services.

What’s included?

Embedded hardware design services our engineering firm provides include simple and complex designs from concept to production. We build embedded systems for modern products, both consumer and industrial. Telecom, consumer electronics, medicine, education – see the range of services we provide to implement embedded hardware for these application areas:

Hardware product design

We often start our work by checking the feasibility of your product idea. After analys ing the project specification and all input data, our technical specialists may suggest several approaches to design and build your device. During the development, your product may undergo several iterations and reviews to achieve the desired result. Depending on your requirements, Integra’s engineering team is ready to provide a full range of hardware product design services.

ing the project specification and all input data, our technical specialists may suggest several approaches to design and build your device. During the development, your product may undergo several iterations and reviews to achieve the desired result. Depending on your requirements, Integra’s engineering team is ready to provide a full range of hardware product design services.

Prototyping and assembly

After the embedded board design and manufacturing, we assemble PCBA to make prototypes. We have all the required equipment in-house to solder electronic components to a PCB. This is needed for testing and verification of the product. If we find any fault in the prototype, we rework it. Two or three iterations are usually enough to reveal most of the errors.

Testing, validation, and certification

We perform functional verification tests, product safety tests, and environmental tests on the prototype. After our embedded hardware developer validates the prototype, it needs to be certified according to the required standards. We also ensure the hardware is backed up by ecology compliance (RoHS) and some country-specific and device-specific certifications.

Preparing for manufacturing

Even though our electronic development service does not include manufacturing of the devices we create, we can connect you with companies and people who do, while providing all necessary design documents needed to manufacture hardware: assembly drawings, Gerbers, and other PCB production files, bill of materials (BOM) or product structure, 3D models, and testing instructions.